Our Services

The Corrosion Solution BUILD TO LAST FOR CENTURIES WITHOUT MAINTENANCE

Rock Bolting

Composite rebar anchors stabilize fractured rock in tunnels and slopes while avoiding corrosion in wet, aggressive ground conditions.

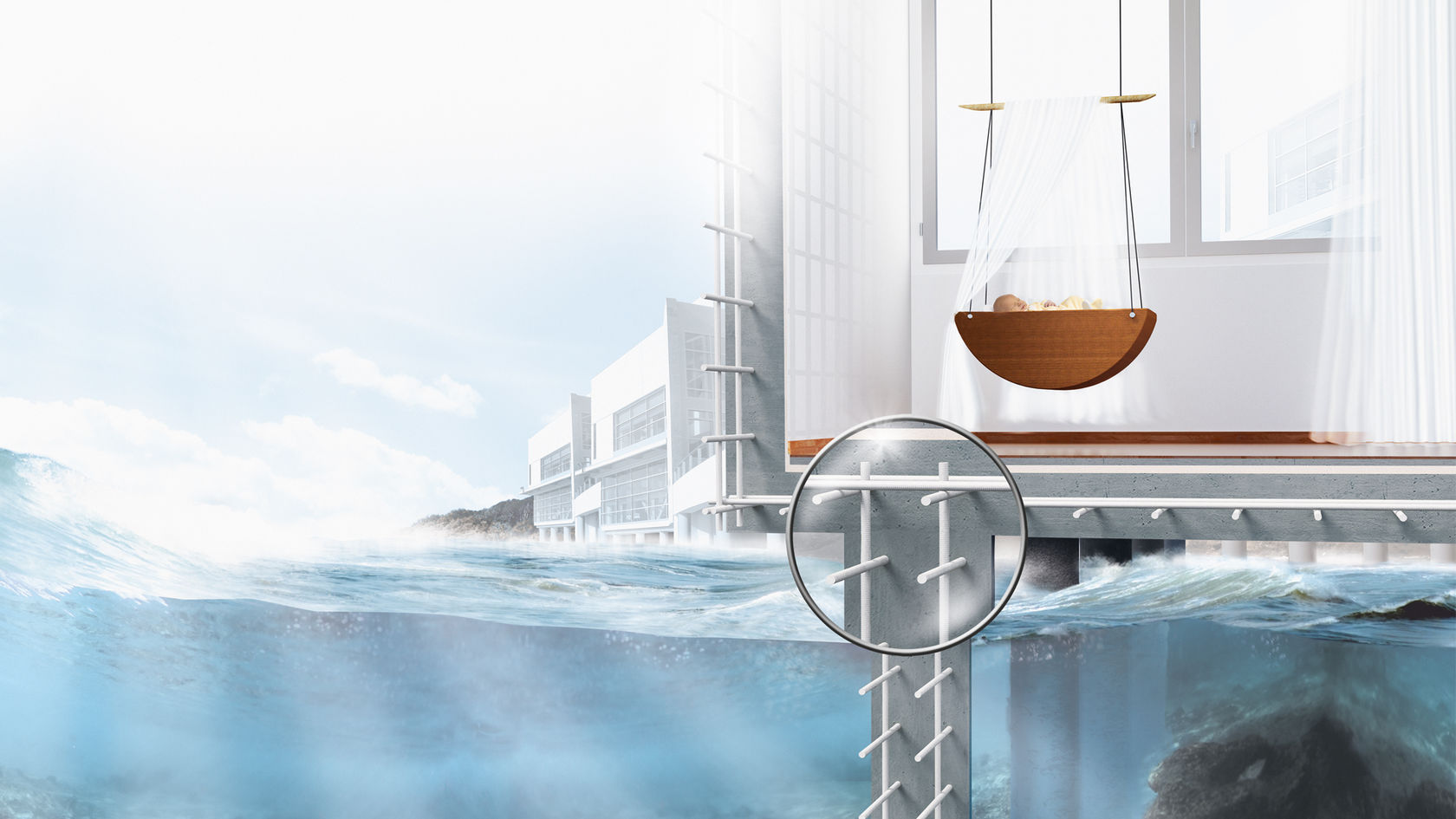

Marine & Waterfront Structures

Marine & Waterfront Structures: Non‑corrosive GFRP rebar reinforces piers, docks, and bridge splash zones exposed to saltwater and waves.

Water treatments

Water treatments: Chemically resistant fiberglass rebar reinforces tanks and plant structures where chlorides and process chemicals attack steel.

Seawalls

Seawalls: GFRP rebar provides long‑life reinforcement for seawalls and bulkheads constantly exposed to tidal splash and chlorides.

Why Choose Us

- Zero corrosion: 100% resistance to any & all harsh environmental factors, No rusting

- High chemical resistance: Impervious to salt and other chemical attacks

- High tensile strength: 2 x stronger than steel with tensile strength of 1000MPa

- Light weight: 4 x (i.e. 73%) lighter than steel, (2100 Kg/m3 vs.7800 Kg/m3), Ease of transportation

- Low thermal conductivity: Makes it suitable for use in hot and cold environments, power plants

- High fatigue life: 20 x higher resistance under cyclic loading (440,000 cycle vs. 40,000 cycle)

- Non-Conductive, & Non-Electromagnetic: Ideal for high electrical field, e.g. power stations

- Non-Magnetic: Ideal for hospitals, MRI rooms, laboratories & other uses

- Low thermal conductivity: Makes it suitable for use in hot and cold environments, power plants

- High bonding strength: Much greater bonding strength to concrete (20 Mpa)

- Long life span: over 100s of years life span (GFRP) vs 25 years (Black Steel)

- Ease of cutting & handling: Faster & cheaper installation and site handling

- Fire rated: Capacity to stand for more than 3 hours in direct fire with minimum concrete cover

- Sustainable to environment: Environmentally friendly, less Green House Gases while transporting

- High durability & performance: No maintenance required, No additional project cost, Major savings

- Min. concrete cover: requires minimum concrete cover i.e. 38mm, (2 ½ x less cracking of concrete)

- Detection by GPR: Easily detected by GPR

- No waterproofing: For bridge decks, unique saving for future

Applications

Concrete Structures Subjected to De-Icing Salts & Chlorides

• Bridge decks & Parapets, deck replacement

• Highway paving

• Road side barriers, Median barriers

• Concrete slabs, Approach slabs

• Parking Structures

• Precast elements, deck panels, box culverts

• Continuous RC Paving

• Infrastructures in persistent corrosive climates.

• Retaining walls

• Piles & Columns, pipe rings

• Structural Strengthening & rehabilitation

Tunneling, Mining & Railway

• Tunneling; e.g. TBM ring precast segments; Soft eye • Sequential excavation or NATUM Tunneling • Rock bolts & Soil Nailing • Precast ring segments • Rail traverse (plinth) 100% GFRP Bars

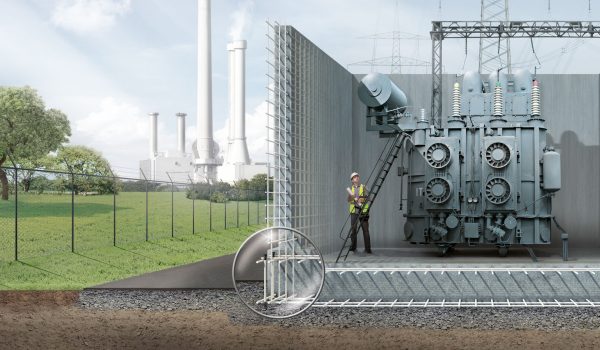

Energy and industrial facilities reinforcement

• High Voltage Substations • Electrical power plants • Chemical Plants • Nuclear Power Plants • LRT’s & Heavy Rail (electrical mitigations) • Waste Water Treatment Plants

Electromagnetic Fields

• Hospitals & MRI Rooms • Radio frequency areas • Airports and runway

Marine & Chemical Chloride Environments

• Coastal construction exposed to salt spray • Seawalls, wharfs & dry docks • Desalination intakes • Dams and port aprons • Swimming pools

Approvals

- American Concrete Institution (ACI-440.3)

- ASTM D7957

- Canadian Standard Association (CSA-S807)

- ISO 9001:2008 Quality Control BSI-British Standard Institution

- MTO qualified for Grade III (DSM)

- FDOT Approved GFRP manufacturing plant

Design Manuals

- Canadian Standard Association (CSA)

- CAN/CSA-S6-06: (2006) Fiber Reinforced Structures, “Canadian Highway Bridge Design Code” Canadian Standards Association, Pages.693-728

- CAN/CSA-S806-02: (2007) “Design and Construction of Building Components with Fiber- Reinforced Polymers” Canadian Standards Association

- American Concrete association (ACI)

- ACI 440.1R-06: (2006) ”Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars.

- ACI 440.5-08: (2008) ”Specification for Construction with Fiber-Reinforced Polymer Reinforcing Bars.

- ACI 440.6-08: (2008) “ Specification for carbon and Glass Fiber –Reinforced Polymer Bar Materials for Concrete Reinforcement

- AASHTO

- AASHTO GFRP-1: (2009) ”AASHTOLRFD Bridge Design Guide Specifications for GFRP-Reinforced Concrete Bridge Decks and Traffic Railings”, American Association of State Highway and Transportation Officials

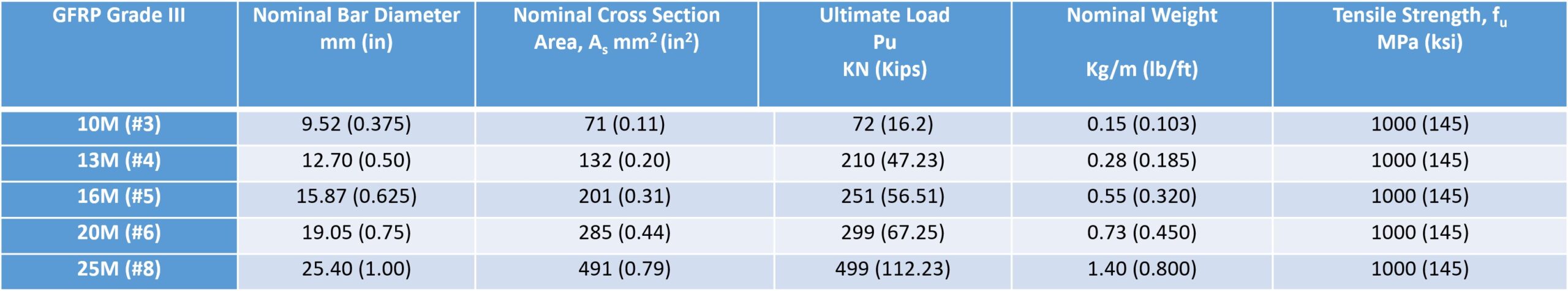

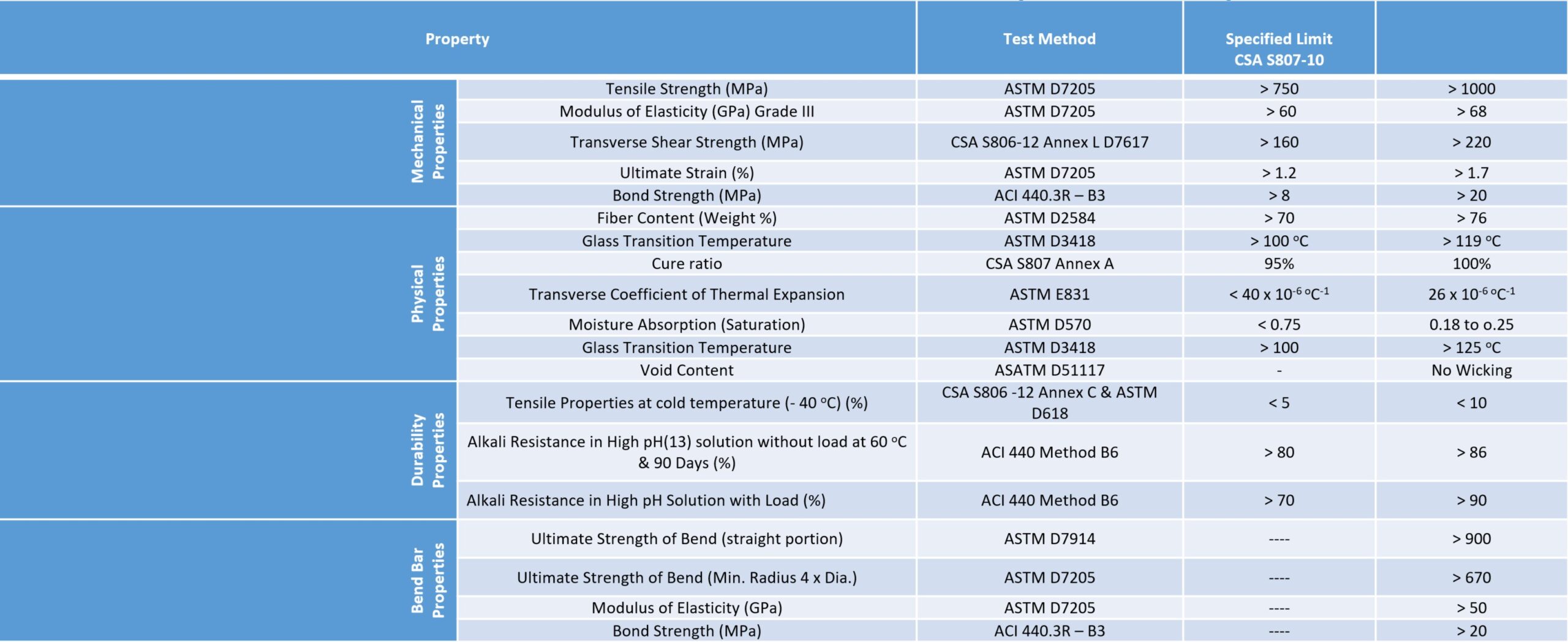

MST-Bar Grade III Rebar Technical Data Sheet (Metric Units)

Client Testimonials